Carbon-neutral silicones for façades - Changing the face of world cities

With around 11% of carbon emissions being generated by building materials, an enormous and ongoing effort is required of manufacturers to continually reduce levels of embodied carbon. In the process of producing silicones, silicon metal production is the biggest contributor to carbon emissions. Carbon-neutral silicones can help to enable a sustainable design, through material and energy efficiency. Significant reduction of carbon emissions from 60-85% have been achieved just by focusing on energy consumption and raw materials. Dow is the first to develop carbon neutral high-performance bonding silicones.

The carbon emissions from building materials and construction, called ‘embodied carbon’ become more important as energy efficiency increases and can account for half of the total carbon footprint over the lifetime of the building. With around 11% of carbon emissions are being generated by building materials, an enormous and ongoing effort is required of manufacturers to continually reduce levels of embodied carbon.

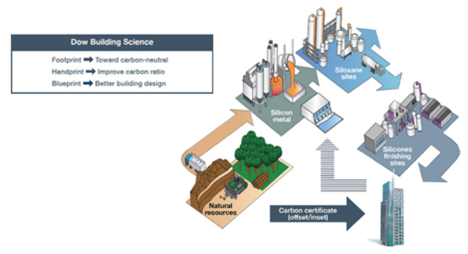

Dow Building Science has a strong commitment to take into account a product’s lifecycle, reduce carbon footprint and as such help address climate change. With more than 50 years of innovation and global leadership in structural silicone glazing, Dow is the first to develop high-performance bonding silicones with externally verified carbon neutrality.

These carbon-neutral silicone sealants for façade have been developed based on their efforts to significantly reduce the high silicon metal footprint and offset the remainder by their own generated offset from within their supply chain.

Sustainable raw material extraction and processing

The biggest contribution to the embodied carbon of silicones resides in raw material extraction and processing. Dow produces silicon metal with low carbon raw materials and renewable, non-fossil-fuel energy. Dow utilizes quartz mines, waste from the wood industry and the Dow-owned eucalyptus plantations. The local production process is supplied largely with hydroelectric power. This allows to significantly reduce the silicon metal’s manufacturing footprint which dominates the overall emissions balance of a silicone production.

Dow is also using its own eucalyptus plantation and reforestation process to help ensure long-term carbon capture capabilities. The faster-growing eucalyptus trees can be regenerated in seven years, offering carbon sinks and raw materials (wood chips and charcoal) for silicon metal production.

Dow Building Science and the ‘carbon journey’

A holistic view of carbon neutrality is important beyond looking at the footprint of carbon-neutral Façade Silicones. Equally important is considering the handprint and blueprint.

The handprint: The carbon neutral Façade Silicones have excellent long-term durability, with applications exceeding 65 years for weather sealants and more than 50 years for four-sided structural glazing silicones. Hence, the ratio between the carbon emitted during silicone production and the carbon emissions saved thanks to silicone’s longevity is very high. A factor of more than 20 has been calculated for insulating glass, as an example.

The blueprint design advantage: Looking beyond, think about the façade design. Silicones contribute to the realization of high-performing structural glazing façades with pure glass aesthetics. Can their use further decrease embodied carbon of the façade or contribute to a reduction of carbon emissions during building operation compared to captive façade designs, for example?

With the global diversity of façade designs and systems, the design technique can have a significant influence on the blueprint.

- Design with less embodied carbon: Structural glazing designs can help save up to 15% of needed aluminum, leading to a reduction of the overall embodied carbon of a façade.

- Energy efficiency: Simulations have shown that specific structural glazing designs can contribute to a reduction of the curtainwall U-value (UCW) of 10-25%, depending on the region and type of façade system.

Leading the way in decreasing the embodied carbon in construction materials, Dow supports carbon-neutral silicones with Verified Carbon Neutrality Certificates, Environmental Product Declarations (EPDs) and comprehensive Life Cycle Analysis (LCA) data.

More information: https://igsmag.com/features/carbon-neutral-silicones-in-facades-a-window-of-opportunity/